| Machineries for Spinning Fibre |  |

The coir yarn is usually spun using traditional charkas which are rotated manually by a woman and the two ladies spin the fibre into yarn through the rotating spindles by moving to and fro The traditional charkhas have been improved by providing a quarter HP motor which yielded better wages to the spinners as well as to the lady who is engaged for rotating the wheel and get only half the wages to that of spinners |

|

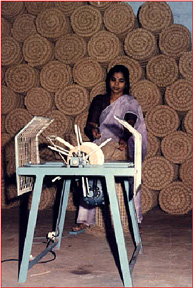

The motorized ratts have further improved the working conditions so that the spinner can now work in sitting posture and spin the coir fibre into yarn in the corner of her house without bothering for inclement weather A compact motorized spinning ratt with a single gear has been designed and fabricated. It is cost effective and requires less maintenance. Patent has been applied for it |

|

The Automatic spinning machines has been developed by CCRI & CICT with multiple heads so as to increase the production and better wages for workers |

|

Designed and fabricated prototypes of Multi Spindle System for spinning coir fibre |

| Machineries for weaving Mats & Matting | |

|

Introduced an improved beaming mechanism working on emery fillets for the preparation of warp beam, Improved the above mechanism by fitting motor thereby increasing the productivity and quality of beaming . Designed and fabricated prototypes of motorized beaming device for preparation of chain beam for 1 meter and 2 meter wide mattings |

|

Fabricated a handloom having fly shuttle for weaving light weight fabric. Introduced a compounded lever and treadle mechanism in the wooden handloom which increased output and reduced physical strain to the weaver Introduced an improved technique for weaving of carnatic mats on loom with two treadles resulting to higher productivity with reduced physical strain during weaving process |

|

The mattinigs in different combination of colours and designs have been developed to suit the customer requirements in terms of aesthetic appeal using different constructions and comfort. It has been possible to reduce drudgery involved in the weaving process by developing 2 shaft and 4 shaft Semi Automatic loom that have been popularized in the coir industry |

|

A fully automatic Power Loom has been developed for weaving coir in different designs. The designs of the loom have been given to two leading exporters for manufacturing the looms |

|

SEMI MECHANISED LOOM FOR MATTING, CARPETS, GEO-TEXTILES. |

|

(LOOMLESS WEAVING OF COIR GEOTEXTILES ( MESH MATTING) A technique for loom less weaving of coir geo - textiles has been introduced so as to engage women workers in the weaving operation to earn better wages |

|

A metallic handloom "Anugraha" has been developed to make it suitable for the women workers for earning better wages. The technology has been transferred to 12 machinery manufacturers. The NRDC, New Delhi conferred the 'Technology Day Award' for the year 2004 to the scientists of CCRI involved in the development of the Anugraha Loom. His Excellency The President of India Dr.A.P.J.Abdul Kalam was the Chief guest in the Award function |

|

A versatile pneumatic loom for weaving mats and matting. The Central Coir Research Institute, Coir Board has designed and fabricated a versatile pneumatic loom ANUPAM for weaving different kinds of mats such as rod mats, rod inlaid mats, loop mats, carnatic mats, creel mats, fibre mats, different kinds of two shaft and three shaft matting, carpets & geotextiles. |

|

The Mobile Fibre Extraction Machine “SWARNA” was developed by the CCRI. The MFEM can be operated by 10 HP Motor/Diesel Engine whereas the existing fibre extraction units are working with 65-75 HP power for operating different fibre extraction machines. Coir Board has received NRDC award for this invention for the year 2010 and the prestigious World Intellectual Property Organization (WIPO) Gold medal has been conferred to India as the best invention of the year 2010. |

|

CCRI has designed and developed a new traditional handloom operated by pneumatic system. This loom can produce different types of mats, mattings, carpets and coir geo textiles easily. Women workers can easily operate the loom. No special training is necessary in this system. It offers high quality with more productivity compared to the traditional wooden handloom and avoids the drudgery in weaving. Thios loom is operated by pnuematic system and pressure produced by air generated from 1-2 hp single phase compressor and utilize the same for stenciling of coir products, an additional advantage of this loom without further investment. |

|

Central Coir Research Institute (CCRI) has designed and fabricated a new versatile multihead mechanized spinning machine without core thread for high production of different varieties of coir yarn. In the conventional automatic spinning machines, the core thread is made out of cotton yarn which creates problems for tufted mats due to difference in the colour. Synthetic yarn had also been used as core thread which is not considered as eco-friendly. |

|

Coir fibres have been successfully blended with other natural fibres like sisal, cotton, silk etc however, the productivity of thinner variety yarn by ratt spinning is very low. Recently, The CCRI of Coir Board has modified the 6 head automatic spinning machine with core thread to spin fine quality blended coir yarn having runnage 1000 meters/kg. The productivity on this “NAVEENA” machine is approx. 18,000 meters of yarn / 8 hours. |

|

This mini tufting machine is developed mainly for tiny units to enhance the productivity with least investment. Hence this invention will help the ordinary entrepreneurs to start mini tufting units for their profit and also give employment opportunity to the unskilled manpower. Women can operate the machine easily for more wages, and earn profit towards the income generation. |

|

In coir industry, there are a lot of coir pith and coir waste fibers getting after some of the process like shearing / defibering. Research on utilization of fiber and pith from green /dry tender husk is being carried out at Central Coir research Institute under Coir Board. Laboratory scale studies could lead to pulping of fiber and pith to produce handmade paper, garden articles, egg carton, visiting cards, gift boxes etc |

|

The Central Coir Research Institute of Coir Board Alappuzha has designed and developed a fully automatic power loom “Anugraha Tejas” for weaving of coir geotextiles. Anugraha Tejas is versatile and can produced 5-6 times more quantity of coir geotextiles of good quality compared to previously developed looms and is also cost effective. Coir Geo Textiles are eco friendly, natural fibre based, durable and cheap when compared to other natural fibre products. |

|

Coir Board has developed a mini fibre extraction machine mainly for the extraction of coir fibre from green tender coconut/ coconut husks available in different areas and temples/ tender coconut venders. Coir pith/powder obtained can be converted into bio manure and use in flori, horti and agriculture purpose. |

Engineering Department