| INTRODUCTION |

The Central Institute of Coir Technology (CICT) is one of the leading research centre under Coir Board established in the year 1979.This institute implements all the S&T programs of Coir Board for the development of Coir Industry. |

| Back to Top |

| OBJECTIVES OF THE INSTITUTE |

Coir Board

Ministryof Micro, Small & Medium Enterprises |

|

| Dr.Shanmugasundaram O.L Joint Director |

| Bio-data |

| |

|

|

I am extremely privileged and honoured to lead a pioneer organization Central Coir Research Institute (CICT) as a Joint Director (Technical). CICT is one of the reputed institute dedicated to the Research & Development activities related to coir technology & Allied Products.

The main objectives are productivity & quality improvement, new-diversified product development, drudgery reduction, manpower reduction by automation, effective by-product & waste utilization are the major important mandates of CICT and have been addressed efficiently through continuous R&D efforts. Eminent Scientists are working with dedication and duty consciousness towards the sustainable growth of coir industry.

If everyone is moving forward together, then success takes care of itself," is one of my personal favorite quotes on teamwork. Teamwork has the incredible power to increase productivity, job satisfaction, and even each person's individual performance. " --Henry Ford "

Coming together is a beginning Keeping together is progress Working together is success. --Henry Ford "

|

|

| VISION |

| Unveiling Excellence: Central Institute of Coir Technology's Dynamic Activities |

| As a pioneering institution committed to advancing the coir industry, CICT stands at the forefront of research, development, and dissemination of cutting-edge technologies. Our activities contribute to the sustainable growth and global recognition of the coir sector. At the heart of CICT's mission is a dedicated focus on research and development. Our state-of-the-art laboratories are equipped with the latest technology and staffed by a team of seasoned scientists and researchers. Through rigorous studies, we aim to enhance the quality of coir products, develop innovative manufacturing processes, and introduce sustainable practices in the coir industry. CICT acts as a bridge between research and industry by facilitating the seamless transfer of technology. We engage with coir entrepreneurs, manufacturers, and businesses to disseminate our research findings, providing them with the tools and knowledge needed to integrate the latest advancements into their operations. By empowering individuals with the necessary skills, we contribute to the overall growth and competitiveness of the coir industry. CICT actively collaborates with international organizations, research institutions, and industry bodies to foster global partnerships. These collaborations not only facilitate the exchange of knowledge and expertise but also position CICT as a key player in the international coir community. Our global engagements contribute to the development of standardized practices and the promotion of coir on the global stage. In line with global efforts towards sustainability, CICT is committed to promoting eco-friendly practices in the coir industry. Through research, awareness programs, and policy advocacy, we strive to minimize the environmental impact of coir production while maximizing its socio-economic benefits. CICT is dedicated to propelling the coir industry into a sustainable and prosperous future. Join us in our journey towards excellence in coir technology! |

| Back to Top |

| RESEARCH ACTIVITIES |

| Evolving Indian standards for coir hard boards. |

| Evolving Indian standards for coir MDF boards. |

| Evolving Indian standards for coir block boards. |

| Evolving Indian standards for coir veneer board. |

| Evolving Indian standards for coir non woven felt. |

| Development of machinery for coir fuel briquettes. |

| Development of coir non woven products from coir. |

| Product development for producing coir composites. |

| Process development for producing coir composites. |

| Development of machinery for weaving geotextile mats. |

| Process development for producing coir non woven felt. |

| Development of double head automatic spinning machine. |

| Evolving Indian standards for machine twisted curled coir fibre. |

| Evolving Indian standards for bristle, mattress and decorticated coir fibres. |

| Application of coir non woven felt for horticultural, geo-technical and composites. |

| Development and standardization of machinery's for producing coir yarn from coir fibre. |

| Development and standardization of machinery's for producing coir fibre from coconut husk. |

| Back to Top |

| EXTENSION |

| Extension is the essential activity for the R & D Institute for the effective dissemination. The institute is extending the service facility to the coir entrepreneurs for making the trial products, improve upon the existing product and for improving their technical capabilities. The entrepreneurs are entitled to utilize some of the equipment's and machinery's installed at our institute by payment of nominal service charges. The facilities extended are: |

| Coir non woven plant |

| The institute has the facility for converting coir fibre into coir non woven felt. The entrepreneurs can utilize the facility of this plant by paying nominal conversion charge. The non woven felt can have further application in geo textile, horticultural and is the base raw material for coir composites. |

| Physical testing laboratory |

| The institute has got BIS accredited laboratory for testing coir and coir products as per,

|

| IS 898 – Specification for retted coir fibre |

| IS 8391- Specification for rubberized coir sheets for cushioning |

| IS 9308 Part 1-4- specification for mechanically extracted coir fibres |

| IS 11060 – Specification of molded rubberized coir cushioning |

The entrepreneurs can utilize the facility of the laboratory for checking their quality of their Products by paying nominal testing charge. |

| Pilot plant for producing coir composites |

| The institute is equipped with the coir impregnation, hot moulding press of size 1.5' x1.5'. The entrepreneurs can make use of this facility to make composites suiting specific applications and further it can be incorporated in their units |

| Pilot plant for producing two ply coir yarns |

| The institute has got the facility of producing two ply coir yarns and the entrepreneurs can utilize the facility of expertise for the production of different varieties of coir yarns and the same can be incorporated in their units. |

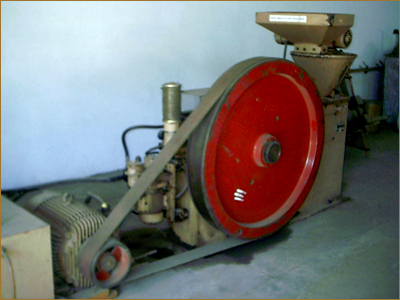

| Coir pith fuel briquetting machine |

|

| Pith Briquetting Machine |

| The institute has the facility for producing coir fuel briquettes from coir pith. The final product has got the excellent utilisation and potential to replace the existing fuels. The fibre manufacturers can make use of this facility for a viable by product. |

| Back to Top |

| |