| COIR

- TRADE INFORMATION |

| Natural retting |

|

|

The fibres which can be extracted from the husk of the coconut are still regarded in many regions as the by or waste product of copra production. These fibre have been processed traditionally into coarse yarns and ropes, floor covering and matting,brushes and brooms and as mattress filler. The processes to obtain a high quality fibre, however, include time consuming retting and labour intensive fibre extraction procedures,. Which are still in common use in Sri Lanka and southern India. |

| |

|

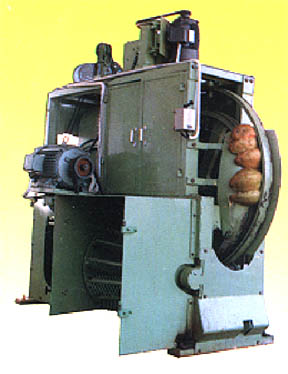

| Defibering machine |

|

|

Although some mechanization of the fibre extraction has been introduced and novel accelerated retting technology has recently been demonstrated to be a substantial improvement, the overall technology remains unchanged. The retting is polluting the surface waters and considered unhealthy for the workers. The existing mechanical defibration procedure is riskful for the hands of the workers and should be improved. The costs of technology development are high and are difficult to raise for a commodity like coir, since the earnings in the fibre production are only marginal and the fibre producers operate on relative small scale at the village level, development of profitable novel products, markets to increase the income of the small holders, is therefore essential.

|

| |

|

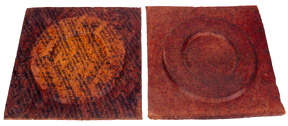

| Door made of Coirply |

|

|

The increased ecological consciousness, especially in Western Europe has led to increased industrial interest in renewable raw materials and environmental safe products. A range of fibre based products have been introduced or are under development in automotive industries, building and construction markets, packaging and consumer goods and others. The Agro technological Research Institute(ATO-DLO) is closely involved in many such industrial technology and product development projects. The market possibilities of coir in certain applications will be evaluated and the prospects will be outlined for the development of a novel technology to produce, starting from the green husks, durable and ecological safe building products like boards, poles and panels. These products potentially can give added value to the unprocessed green coconut husks and substitute for dwindling timber supplies and contributing to reduce deforestation |

| |

|

| Coconut Production |

| Coconut tree |

|

|

Coconut trees are commonly grown in tropical countries, mainly for the high oil content of the endosperm(Copra) which is widely applied in food and nonfood industries (margarine, soaps etc.) Large production areas are especially found on the casts in the wet tropical areas of Asia (Philippines, Indonesia, India, Sri Lanka and Malaysia) In these countries millions of people live on the coconut palm and its products. |

| |

|

| Major Coconut producing countries (Total coconuts in 1000 metric tons) |

Country

|

2016 |

%

|

2017

|

%

|

2018 |

%

|

| Indonasia |

17.722 |

32.1 |

18.983 |

33.4 |

183.000 |

39.1 |

| Philippines |

13.825 |

25.1 |

14.049 |

24.7 |

153.532 |

32.8 |

| India |

11.128 |

20.2 |

11.470 |

20.2 |

119.300 |

25.5 |

| Srilanka |

2.520 |

4.6 |

2.575 |

4.5 |

2.513 |

0.5 |

| Brazil |

2.649 |

4.8 |

2.343 |

4.1 |

2.890 |

0.6 |

| Vietnam |

1.470 |

2.7 |

1.499 |

2.6 |

1.304 |

0.3 |

| Papua New Guinea |

1.191 |

2.2 |

1.203 |

2.1 |

1.200 |

0.3 |

| Mexicao |

1.157 |

2.1 |

1.159 |

2.0 |

1.064 |

0.2 |

| Thailand |

0.815 |

1.5 |

0.895 |

1.6 |

1.010 |

0.2 |

| Tanzania |

0.556 |

1 |

0.556 |

1 |

0.530 |

0.1 |

| Myanmar |

0.532 |

1 |

0.546 |

1 |

0.425 |

0.1 |

| Malaysia |

0.505 |

0.9 |

0.518 |

0.9 |

0.647 |

0.1 |

| Ghana |

0.380 |

0.7 |

0.384 |

0.7 |

0.366 |

0.1 |

| Vanuatu |

0.337 |

0.6 |

0.350 |

0.6 |

0.410 |

0.1 |

| Soloman Island |

0.342 |

0.6 |

0.318 |

0.6 |

0.410 |

0.1 |

Total |

55.133

|

100

|

56.848

|

100

|

468.602

|

100

|

|

| COIR |

|

Besides the nuts, the palm yields husks, shells, leaves and the stem, which are domestically used as raw materials for many products. Commercial production of charcoal from the shell is an increasingly important (export)market outlet for the cocos producing areas.

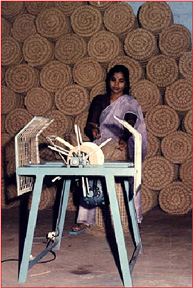

In most areas coir is a by-product of copra production and the husk are left on the fields as much or used as fertilizer, due to the high content of potash, India and Sri Lanka are the main areas where the fibres from the husk(coir) are extracted by traditional methods for production of a variety of products (brushes and brooms, ropes and yarn for nets and bags and mats and padding of mattresses) However, only a small part of the available fibres are being used for these purposes. The average fibre yield is dependent on the geographical area and the variety of coconut trees. In Sri Lanka and the south of India, were the best quality fibres are produced, the yield is 80-90 grams per husk, while the Caribbean husks may yield up to 150 gram of fibres, which are very thick. Hard fibres from coconuts as a commodity have been facing a declining market in the past decades for the traditional products, despite their comparatively low trade value, the fibres provide significant economic support to the population in certain areas of producing countries (South India-Kerala/Sri Lanka) In these areas especially many women depend on coir for their sustenance.

|

| |

|

| Processing of coir fibre

|

Modern retting in concrete tanks

Coir- The Golden Fibre

Coir pith compost used as a manure

|

The traditional production of fibre from the husks is a laborious and time consuming process, which is very polluting. The husks are processed by various retting techniques, generally in brackish water(3-6 months) in pits or salt backwaters, which requires 10-12 months. Novel developments in India(CCRI, Kalavoor) using a biotechnological approach with specific microbial enzymes have reduced the period of retting to a few days.

All these processes are yielding different but also varying qualities of fibers. Generally 56-65% long fiber= 150mm ; 5-8% short fibers=50mm. The fiber fineness varies between 50 and 300mm.

The chemical composition of coir and other plant fibers is usually hand labor. After hackling, washing and drying (in the shade) the fibers are loosened by hand and cleaned. The remaining residual pith, which was considered a waste problem, recently finds new profitable markets as a peat moss substitute in horticultural products.

A mechanical process uses husks after only 5 days of immersion in water tanks. The fibers are opened by crushing in a breaker. By the revolving "drums" the coarse long fibers are being separated from the short woody parts. The stronger fibers washed, cleaned and dried, hackled and combed.

New environmentally friendly methods for the fiber production are of interest, which can be locally exploited on relatively small scales and is yielding a more constant quality of fibres.

|

|